Visit to August Foerster 2015

The Saxony town of Löbau, home to the August Förster piano factory since 1862.

How August Förster pianos are built!

August Förster pianos are built in the time-honoured way. While production line piano factories have invested in CNC machinery (computer numerical control) Förster prefers to keep on with its traditional equipment and hand-building skills. Some of the factory's specialised machines are one hundred years old and still in perfect operating condition! Below a wood press for clamping wood sections together during the glueing process.

The veneer press is of a similar age.

Fallboards in the making. Wooden batons are glued side-on to each other using the wood press above and then faced with veneer.

Tapering the ends of the soundboard ribs.

An upright piano soundboard clamped into position on the wooden frame.

The soundboard bridges are made from solid maple. August Förster choose not to use graphite on the top of their bridges.

An August Förster 170 grand piano outer rim being clamped and glued into position.

Grand piano iron frame after spraying with primer.

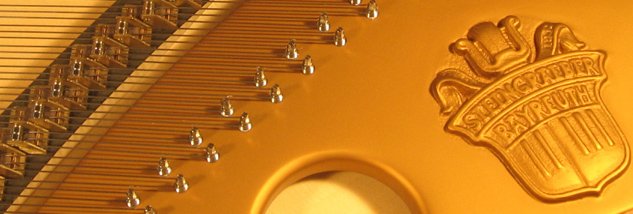

Fitting the strings

Upright pianos ready for keyboard and action installation.

Showing the extra width of August Förster uprights. This allows for longer bass strings and therefore a better bass tone.

The unique back bridge construction employed in August Foerster upright pianos.

Although August Förster have been making pianos for over a hundred and fifty years the definitive sound of today's Förster pianos was largely created by third generation owner and innovative piano designer Gerhard Förster.

Pictured below August Förster 190 (left) and 170 grand pianos.